claire® lh -safety cabinet class II

CLAIRE® LH – THINK TOGETHER

TOGETHER FOR MORE SAFETY IN THE LABORATORY

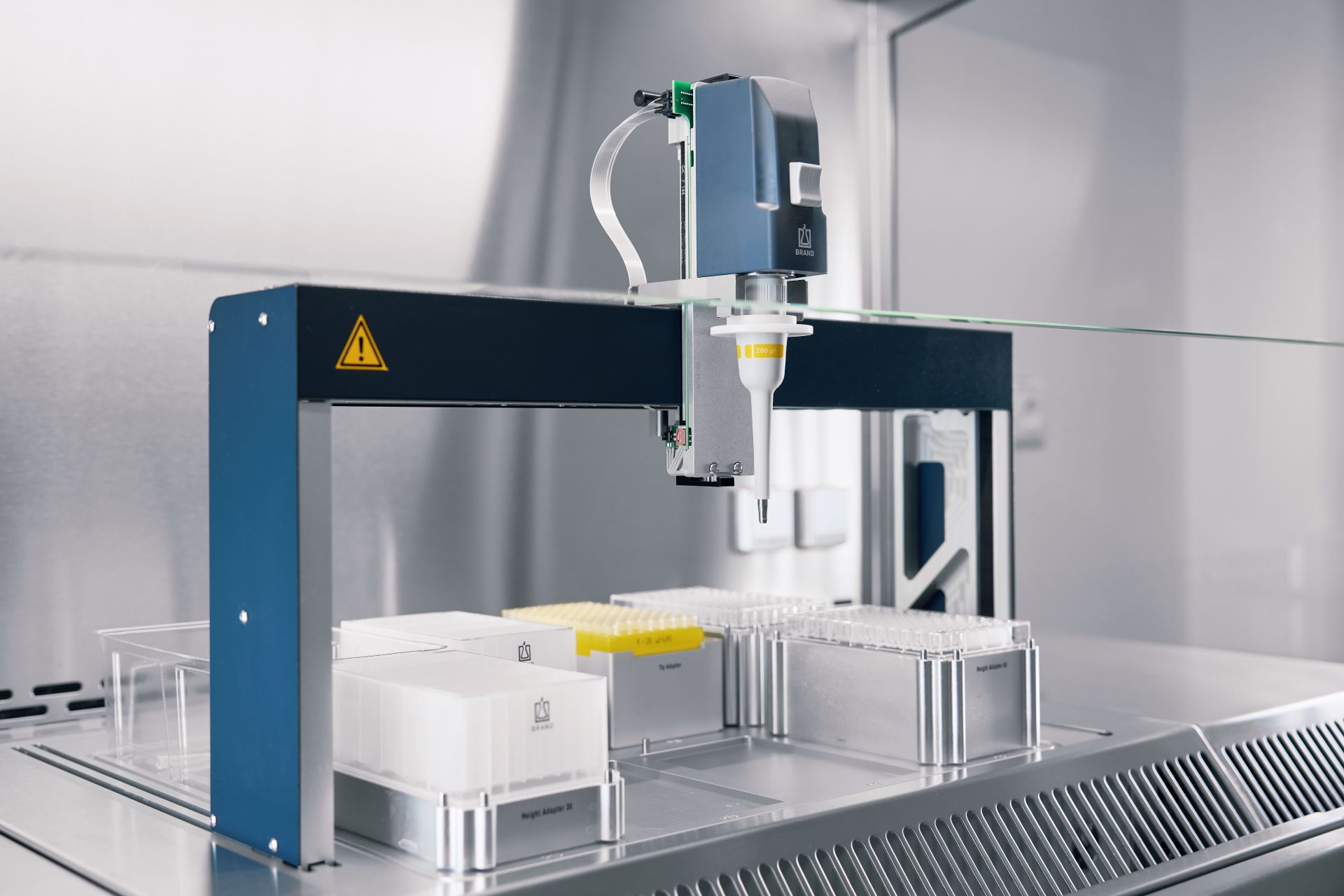

The integration of the BRAND Liquid Handling Station in a Berner safety cabinet of the claire® series thus results in a unique combination. Reliable sample processing in a GMP-A environment, tested according to DIN EN 12469 for personal and product protection, is thus combined with innovative user-friendliness and high-quality carry-over protection.

Safety cabinet claire® lh - at a glance

Tested safety for people and products

In the tested and unique combination with the BRAND liquid handling station, the claire® lh fulfils the requirements for personal, product and carry-over protection according to DIN EN 12469 - as evidenced by the CE declaration of conformity.

Intuitive pipetting process

A laptop connected to the claire® lh takes over the control of the methods. Without programming knowledge, you can define the processes and have them carried out automatically. The software reliably informs you about every step of the method.

Safe results

The high-quality system solution consisting of a safety cabinet and pipetting robot enables you to work under GMP-A conditions for the highest quality requirements in your processes.

Highest safety in operation

The intelligent locking mechanism guarantees your safety during the pipetting process. After loading the Liquid Handling Station, it switches to pipetting mode: The front window is closed to such an extent that unintentional reaching in is not possible.

A wide range of possible applications

Quickly adapt the features to your requirements. The compact design allows up to eight workstations. These can be individually equipped - from single vessels to 384-well plates. The right accessories, such as shakers, are available for every application.

Lifelong quality

Berner Service supports the product throughout its entire life cycle. From commissioning to annual maintenance and technical support, we are there for you at all times and are at your side with our expertise - for the safety cabinet and the liquid handling status. Find out more about our service here.

Individual positioning

You design the individual workspace according to your wishes and requirements. Depending on the process and task, the liquid handling status can be positioned flexibly to the left, right or center

Ergonomics

Particularly quiet, bright operating conditions, individually adjustable working surface height and optimum legroom thanks to the particularly compact design of the first main filter stage.

Dual advantage

In addition to using the combination, the claire® lh can also be used without the easily removable Liquid Handling Station (LHS). With optional standard worktop configuration, a class II microbiological safety cabinet is always available for all further laboratory work.

Sustainability - Made in Germany

Both the safety cabinet and the liquid handling station are manufactured in Germany. Due to the high proportion of German suppliers, the supply chains are short. Assembly and technical testing are carried out directly by the manufacturer - guaranteeing you the "Made in Germany" label

VERSATILE PIPETTING ROBOT

The Liquid Handling Station from BRAND GMBH + CO KG offers high flexibility for changing pipetting tasks. Seven workstations in ANSI/SLAS format can be freely assigned, for example with single tubes, 8-well PCR tube strips, reservoirs, 96-well and 384-well plates. For contact-free liquid dispensing, 1-channel and 8-channel liquid ends are available. The right accessories are available for every application, such as a shaking and temperature control module or cooling blocks

INTUITIVE PIPETTING PROCESS

The pipetting process can be controlled using a laptop connected to the claire® lh, so no programming knowledge is required. The software takes over the control and carries out defined processes automatically. The LHS automatically logs the processes and checks them for inconsistencies. Compared to manual pipetting, the use of the LHS achieves a time saving of 70%.

EQUIPMENT & OPTIONS

The claire® lh system solution comprises the combination of BRAND's Liquid Handling Station and the high-quality safety cabinet, based on the model size B-2-130 in the design of Berner's claire ® pure series.

Delivery scope:

- Modified three-part worktop set

- All connections for power supply to the LHS and for connection to the safety cabinet control unit

- USB interface for connecting a PC or notebook* for operating the LHS on the left side

- Liquid Handling Station software + basic equipment

- versatile, ergonomically adjustable base frame in 7 steps between 683 mm and 952 mm

- Filter test connections

- Functional socket in the work area

- Preparation for additional sockets or interfaces

- Powerful system for UV-C disinfection

The high functionality of the safety cabinet can be usefully supplemented with the range of options for all essential applications, e.g. with an electric lifting underframe. A comprehensive range of accessories is available for the liquid handling system. Talk to our sales department about this. * Notebook or PC must be provided separately by the user and are not included in the scope of delivery.

Further information on the BRAND Liquid Handling System can be found here.

Deutsch

Deutsch

English

English